OUR WORK

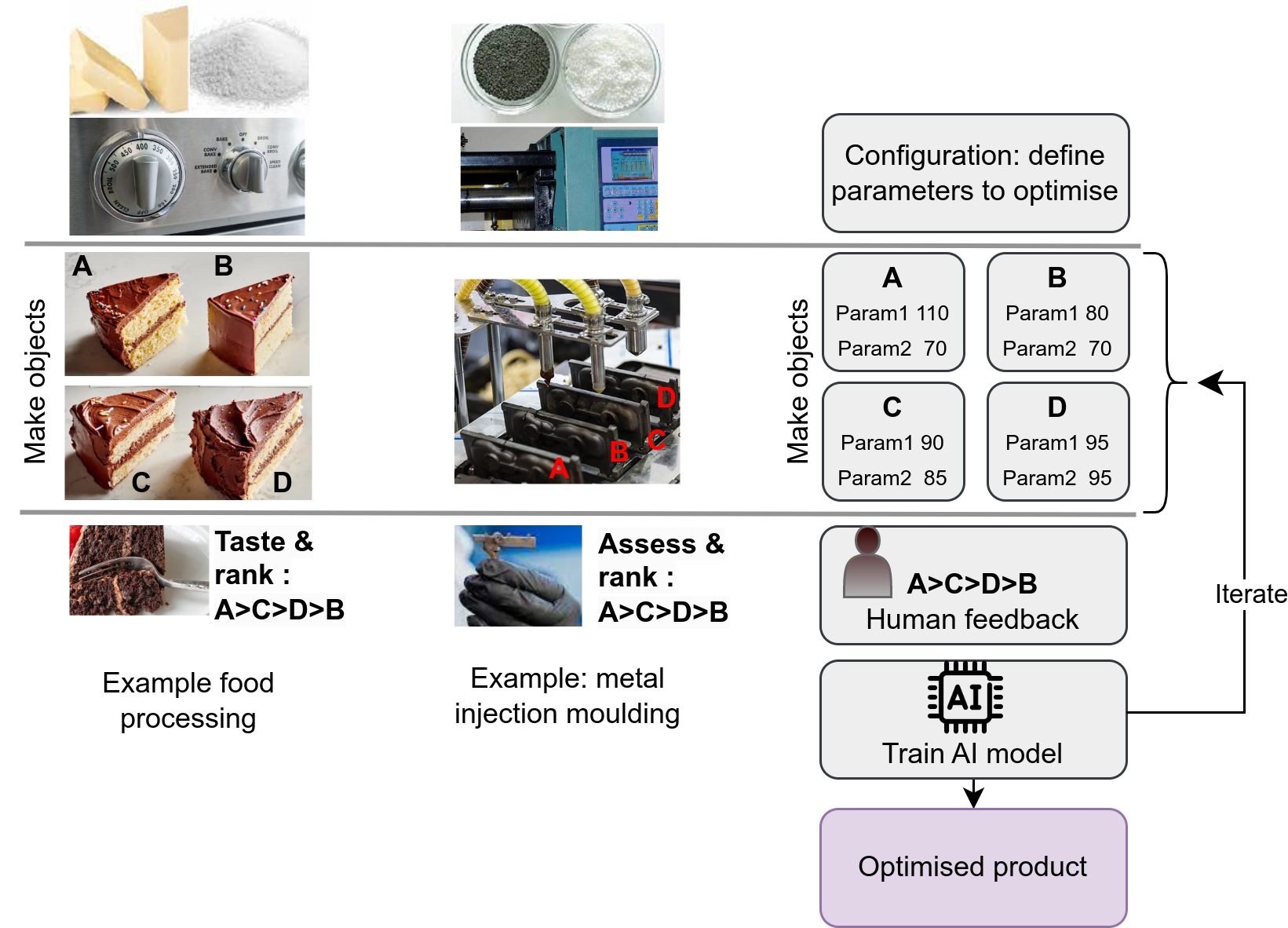

Have you ever faced the disappointment of your manufactured product not turning out as desired? The "recipe" you are using may not always produce the desired result, leaving you wondering which parameters to change next in order to maximize the product quality. HLOOP aims to automatise and simplify process optimisation in manufacturing. It uses your qualitative (or quantitative) feedback about the quality of your product to quickly optimise your manufacturing parameters and process. Let's consider for example the process of baking a cake (figure-left). What is process optimisation in this case? Firstly, we carefully select the parameters to optimise, like amount of butter, sugar, and oven temperature. Next, we may experiment with four different recipes, each resulting in a different cake. We then taste each cake and rank the recipes based on our preferences. Using this valuable human feedback, HLOOP can iteratively improve the recipe until we achieve the perfect cake (figure-block-diagram). Remarkably, this approach can be applied to a wide range of manufacturing process to achieve optimal products/processes, such as for instance in coffee roasting (figure-centre) and additive manufacturing (figure-right).